August is our birthday month here at Threds and we are celebrating 25 years of service by sharing a timeline of how far we have come since 1994.

Rooted in humble beginnings, Threds officially launched in August of 1994 as a retail clothing store selling restored vintage jeans. Screen printing followed shortly two years later in 1996. To highlight our screen printing origins, we've provided a few tips on how to brand on a budget utilizing our services.

When planning a custom T-shirt order on a small budget, consider the following:

Select a simple 1-2 color design that will reduce the cost of your overall spend while still being able to maximize your logo or message.

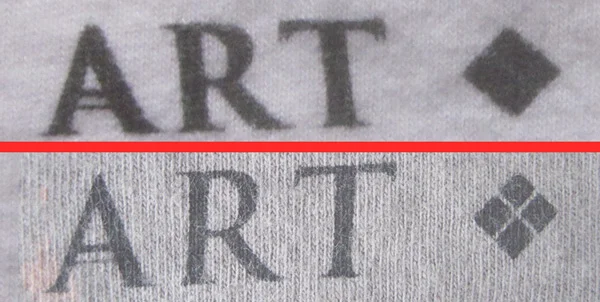

Utilize a one-print location verse multiple print areas on the garment. You can maximize brand visibility with a single front or left chest print option, like the examples below.

Comfort over brand name. Consider using a cheaper brand of shirt that can provide the same level of comfort. You’ll save on costs, but not at the expense of quality.

In 1997, Threds included promotional offerings into our business portfolio. This allowed us to expand our overall custom branding capabilities and garner more corporate business. Check out our pick of the top 5 go-to promotional items for any occasion:

1. Drinkware

2. Tote bags

3. Writing instruments

4. Koozies

5. Notebooks

Embroidery joined the family of offerings in 1999 to service clients who wanted a more formal branded apparel look and feel. Check out our list of items that are the best fit for embroidery services:

1. Polo shirts

2. Fleece

3. Hats

4. Jackets (non-waterproof)

Finally, in 2003 Threds introduced a fulfillment and e-commerce division, making us a full-service branding powerhouse with a national footprint. What does this service do for customers?

It provides an entire team of creative thinkers, committed to developing branded merchandise that resonates with your customers.

We have a dedicated account & design team that understands your brand.

Customer Service needs are handled in-house.

Our e-commerce division provides fast, affordable shipping options and tracking.

Design, production, inventory and order fulfillment all under one roof.

We provide accurate product sales and inventory reports.

Let Threds be a part of your brand’s story. We’ll do more than produce it; we’ll help you tell it. Start your custom apparel or promotional project today!